The “left” or “right” version is fixed at the upper die with the nut in front.

On the lower die the keys are placed mirror-inverted.

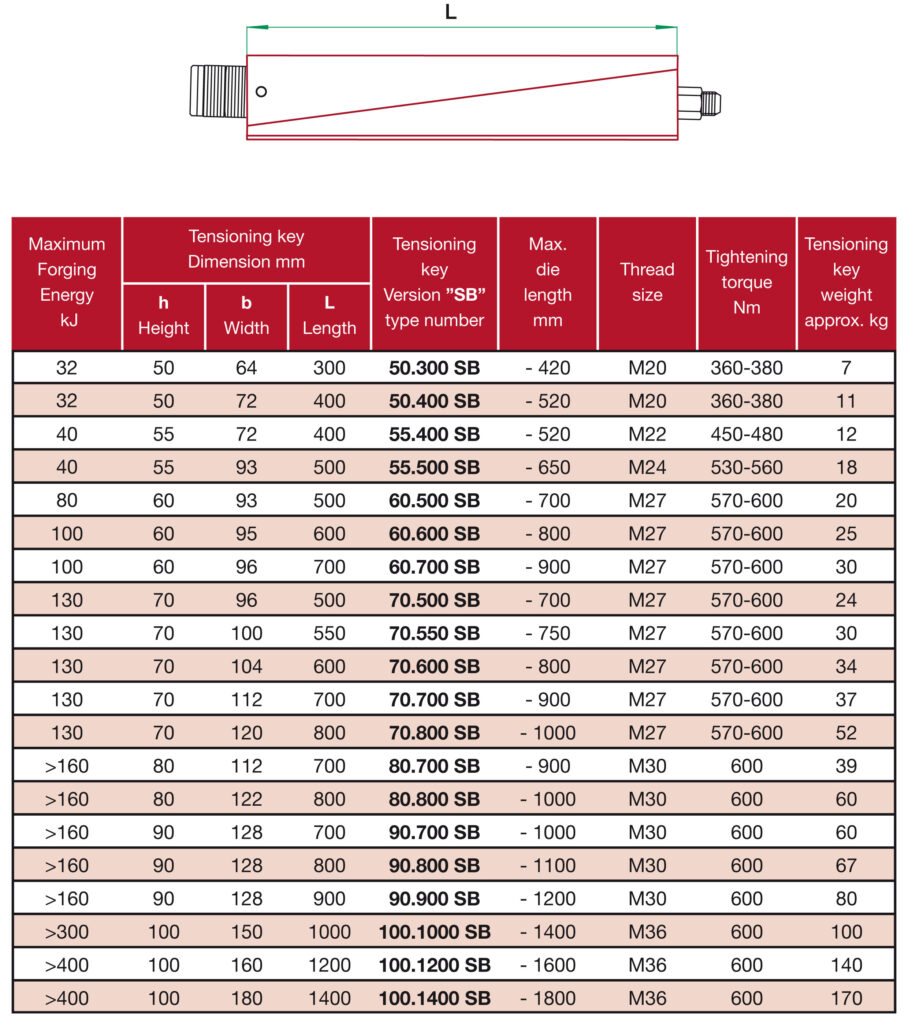

Dimensions and weights tensioning key version “SB”

Feuerbacher tensioning keys are also available in other sizes.

Please contact us for further information.

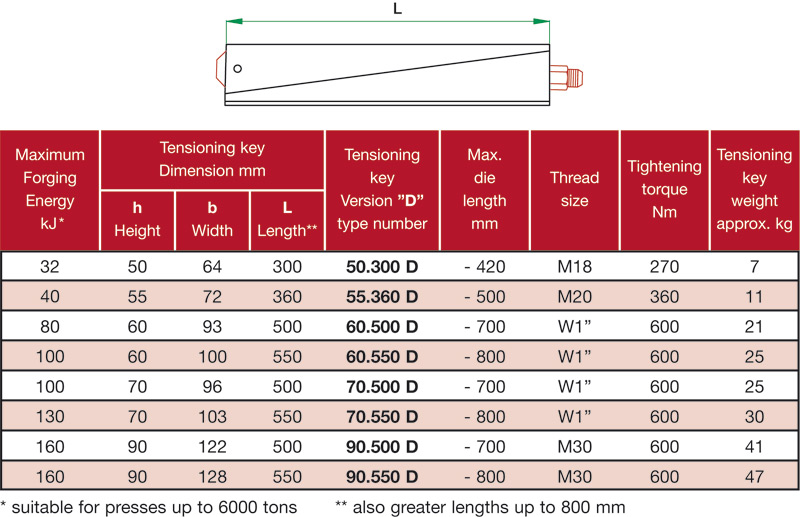

Feuerbacher tensioning keys are also available in other sizes.

Please contact us for further information.

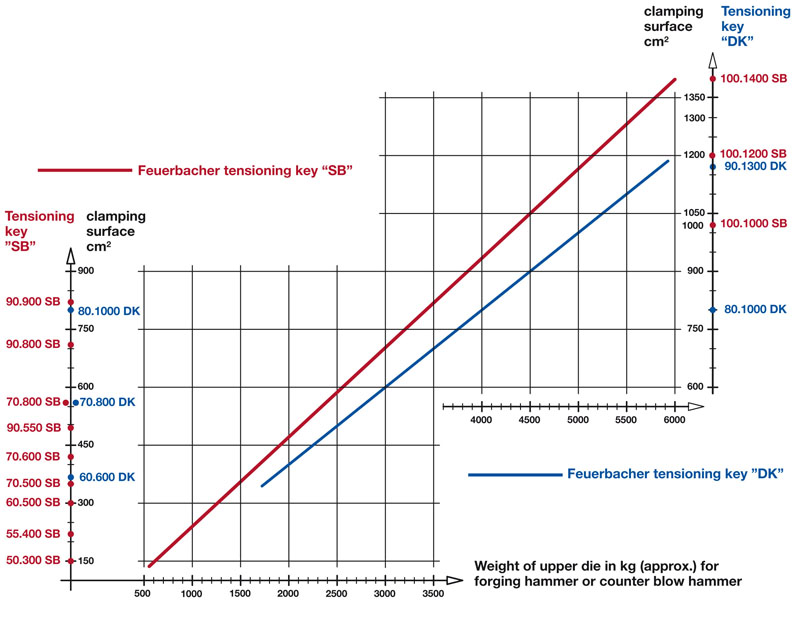

Guidance values for tensioning key sizes and forging the weights applicable to tensioning key range “SB”

Feuerbacher tensioning key “SB”

Clamping force approx. 4.0 kg per cm 2 of contact face

– Full contact between surfaces of key halves

– Supporting clamping screw

– Angles 5º/15º

– Externally mounted cup spring set

Feuerbacher tensioning key “DK”

Clamping force approx.

5.0 kg per cm

2 contact surface

– 2 counter acting clamping key halves each

with externally mounted cup spring set

– Fully supported contact faces of key halves

– End to end clamping screw

– Angles 5º/15º

those who

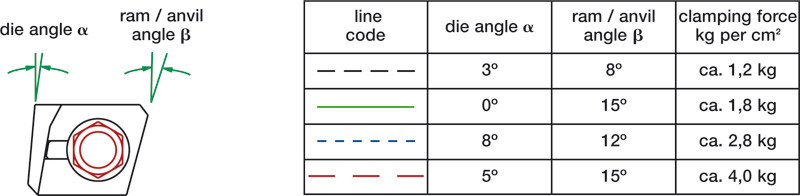

hold The “Feuerbacher tensioning key” in standard versions has angles of 5° and 15°. Other versions are available if necessary for special applications.

The difference between the hammer / press-side should not be less than 5° by using in this. The smallest possible slant on the anvil bed is 8° and on the die side 3°.

small drop-forge blocks, inserts

For small drop-forge blocks and especially for die inserts in anvil caps, it is possible to use a 0° slant on the die side. In this case the difference

between both clamping surfaces should not be less than 10°.