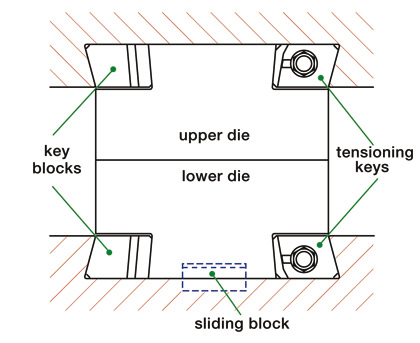

Feuerbacher tensioning keys on one side

To correct positioning in the left to right

direction additional spacing shims must be provided for either the upper or the lower die. The arrangement is suitable for anvils

and rams of varying widths without dovetail configuration.

To compensate for differences in the width shims of different thicknesses are employed.

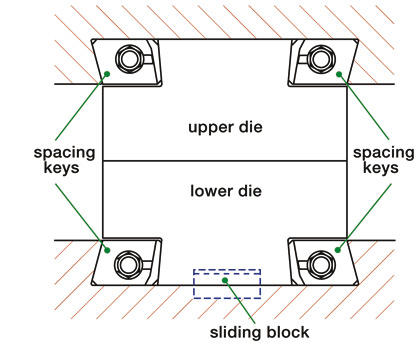

Arrangement with 2 Feuerbacher tensioning keys

at the top and 2 at the bottom

Either the upper or lower Feuerbacher tensioning keys

can be used to correct for lateral offset.

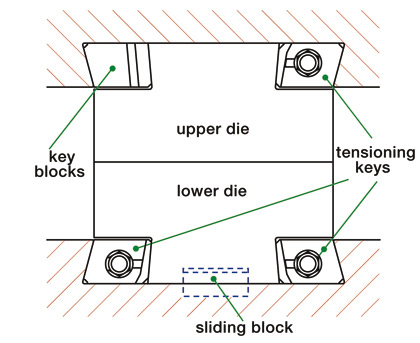

One Feuerbacher tensioning key at the top and two Feuerbacher tensioning keys at the bottom

This clamping system may be considered as the standard arrangement for hammer dies. The upper die is clamped using a clamping key on the one side and a parallel shim on the other.

The bottom die is located by a sliding block and is then aligned in the length direction making use of the two Feuerbacher tensioning keys.

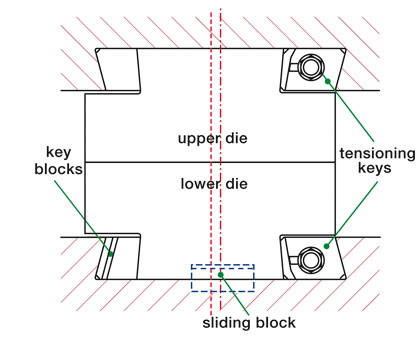

Arrangement with Feuerbacher tensioning keys

on one side, with lateral offset of die insert

The die insert is set up off center relative to the die space.

The position of the die cavity is such that it will then

be central in the machine.

The shims may have to be narrower than the

Feuerbacher tensioning keys.

One sided clamping

with direct location on the other side

The upper die is located on one side in the top dovetail.

To align the lower the spacing shims are employed on one side.

The shims are selected to correct for lateral offset.

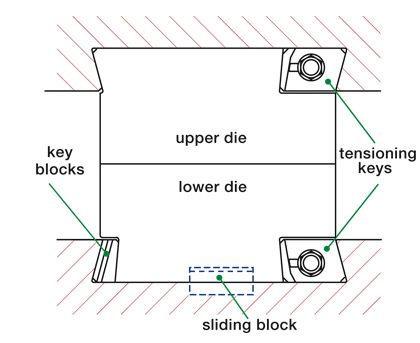

Die holder design

Die holder for forging using a one piece die insert.

The parts of the die holder are in each case clamped with a Feuerbacher tensioning key. Sliding blocks are provided for both

the upper and lower holder for alignment in the length direction.

.

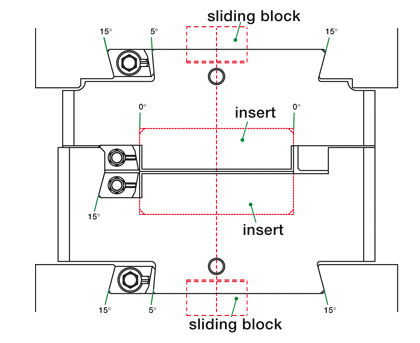

Each of the 2 inserts are fixed using Feuerbacher tensioning keys. For changeovers only the die inserts have to be exchanged.

Mounting of the inserts in the holders

In this example the die holder is fixed by “Feuerbacher tensioning keys”. The holder has a sliding block (dowel) at the top and bottom. The longitudinal offset of the holder is adjusted at the upper sliding block and the lateral offset by the lower shims. By this the position for the inserts can be easily adjusted.

The upper die insert has no lengthwise or lateral clearance. At the lower die insert shims are used longitudinally and laterally to compensate offsets.