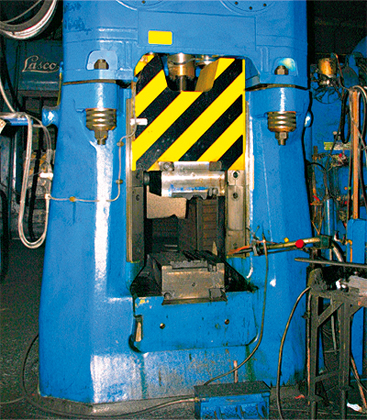

Hydraulic down stroking hammer

Year of construction 2007

Impact energy 25 kJ

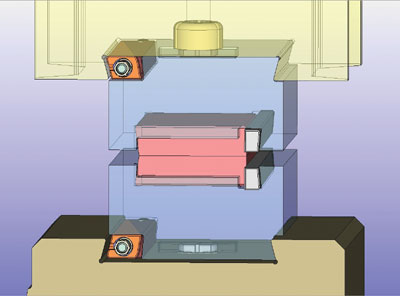

Weight of built-in upper die approx. 350 kg

Max. permissible weight approx. 1200kg

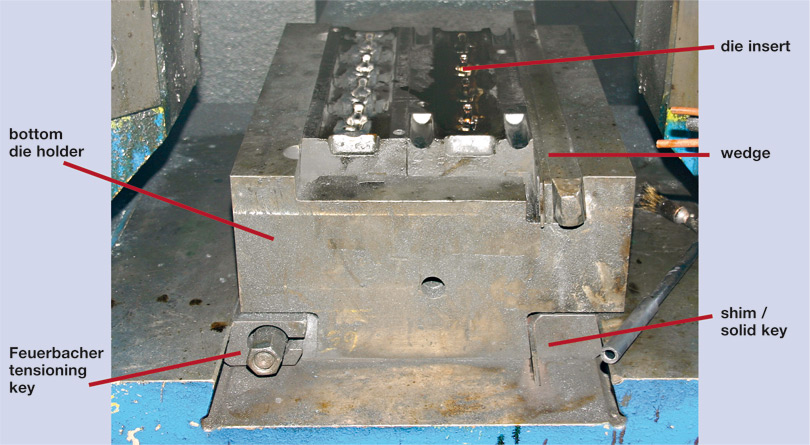

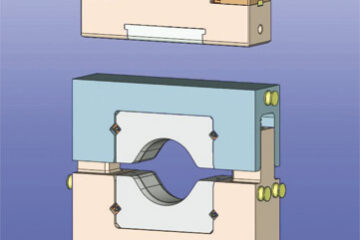

Feuerbacher tensioning key 60.550 SB

Height 60 mm, width 94 mm, length 550 mm

Externally mounted cup spring washers

Fully supported vertical contact face

Supporting clamping screw

Thread M27

Angles 5º/15º

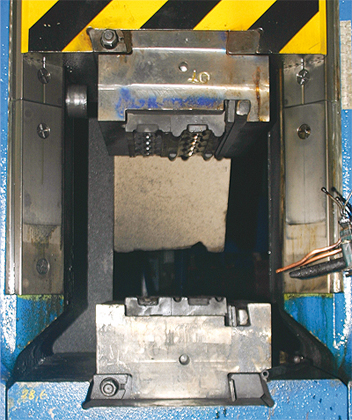

The die holder is used for single and multi-part die inserts.

The parts of the holder are each clamped by means of a Feuerbacher tensioning key and a shim. Both keys are provided with a block insert to prevent longitudinal displacement.

When exchanging the die only the die inserts must be replaced. The base holders remain in the hammer.

The offset in the die can be adjusted by using thin metal shims.

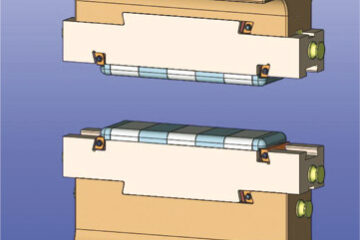

In this case the inserts themselves are clamped using conventional wedges.

Detail – bottom die

As an alternative to using a shim, the holder can also, on one side, be clamped directly against the ram or the anvil bed.

The advantage of this possibility is the

greater contact area of the impact faces.

Thereby the tendency for tiling is considerably reduced.

0 Comments